sites in 2020 resulted in a reduction in energy use of 1.27 million gigajoules and associated emissions reduction of approximately 79,500 metric tons of CO2. Projects implemented in our European and U.S. In 2020, we expanded our assessment of flare systems at our major sites with the aim of optimizing our product recovery rates in flare gas recovery systems, minimizing steam and optimizing supplemental gas associated with flare operations. We are evaluating and deploying solutions at our most energy intensive manufacturing sites to reduce carbon emissions, including the use of lower carbon-intensive fuels and process, and energy optimization. Our innovative low-density materials help make cars lighter, and our oxyfuels improve fuel efficiency and reduce vehicle emissions including GHGs. We also offer products that help avoid emissions during their use phase. An independently reviewed life cycle assessment study demonstrated that the carbon footprint of these polymers is reduced by up to 75% when compared with a fossil-based polymer. These renewable-based polymers are branded under our family of sustainable solutions called Circulen. In 2019, LyondellBasell achieved the first parallel production of polypropylene and low-density polyethylene made from renewable raw materials, including bio-based wastes and residue oils, as an alternative to fossil-derived resources.

Products that lower GHG emissions across the life cycle TCFD provides a framework to further strengthen governance, create strategy, assess risk and establish metrics that will guide our efforts as we strive to improve our sustainability.īeyond our operations, we aim to develop a range of products that contribute to a low-carbon economy through their use or how they are manufactured. We currently use the CDP Climate Change framework to report our climate risks and impacts, and have expanded our approach using the Task Force on Climate-related Financial Disclosures (TCFD) recommendations in 2021. You can find out more about our targets by visiting our page here. Our climate-related goals are support the ambitions of the Paris Agreement and the transition to a low-carbon economy. The rest of the stages of the process are considered indirect emissions, since they are still associated with the activity or product, even though the person or business does not have direct control over the process of the stage.LyondellBasell is working to reduce our operational CO2 footprint and collaborating with our value chain partners to deliver more sustainable solutions, products and technologies to the market.

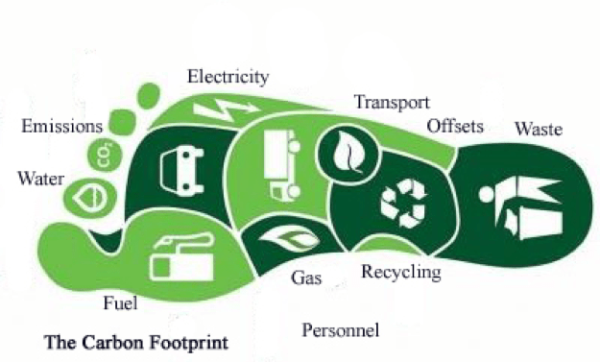

In each stage, there is an organization or person capable of measuring, controlling, and managing the necessary energy and the emissions of a process (the truck driver, managers of the manufacturing process, the user of the product, etc.). These would be considered the direct emissions generated in this stage by this person or organization. Throughout the life cycle of any product or service that we use as individuals or organizations, we can differentiate distinct stages that require energy and generate GHG emissions: from the extraction of the raw materials, the transportation to industry where they are transformed into products, the distribution to vendors, the use by consumers, and finally the waste treatment where they may be transformed again. Therefore, the following formula sums up the calculation:Ĭarbon footprint = Activity data x Emission factor

#Low carbon footprint iso#

The carbon footprint calculation is based on international standards like the GHG Protocol and ISO 14064. Emissions are calculated by multiplying the consumption data by its emission factor, depending on the fuel used, type of energy, and the intended activity.

0 kommentar(er)

0 kommentar(er)